Case Studies

Fibre Optic and PoE NEtwokrs in Naval Destroyers & Aircraft Carriers

Overview:

Modern naval vessels rely on mission-critical networks that seamlessly connect navigation, weapons control, surveillance, and communications systems. A leading defense contractor selected the Omnitron iConverter and RuggedNet products to modernize shipboard networking infrastructure—delivering rugged, space-efficient, and compliant solutions engineered for reliable performance in harsh maritime conditions.

The Challenge

The project involved upgrading and hardening shipboard networks aboard naval destroyers and aircraft carriers. The technical and environmental challenges included:

Ruggedization: Network devices needed to operate reliably under intense shock, vibration, humidity, and temperature extremes at sea.

Environmental Protection: Specific deployments required custom conformal coatings to defend against salt fog, humidity, and corrosive marine atmospheres.

Space Efficiency: Equipment had to integrate into limited rack and compartment spaces without sacrificing performance.

Regulatory Compliance: All components were required to meet stringent U.S. trade and manufacturing standards, including TAA, BAA, and NDAA compliance.

The Solution:

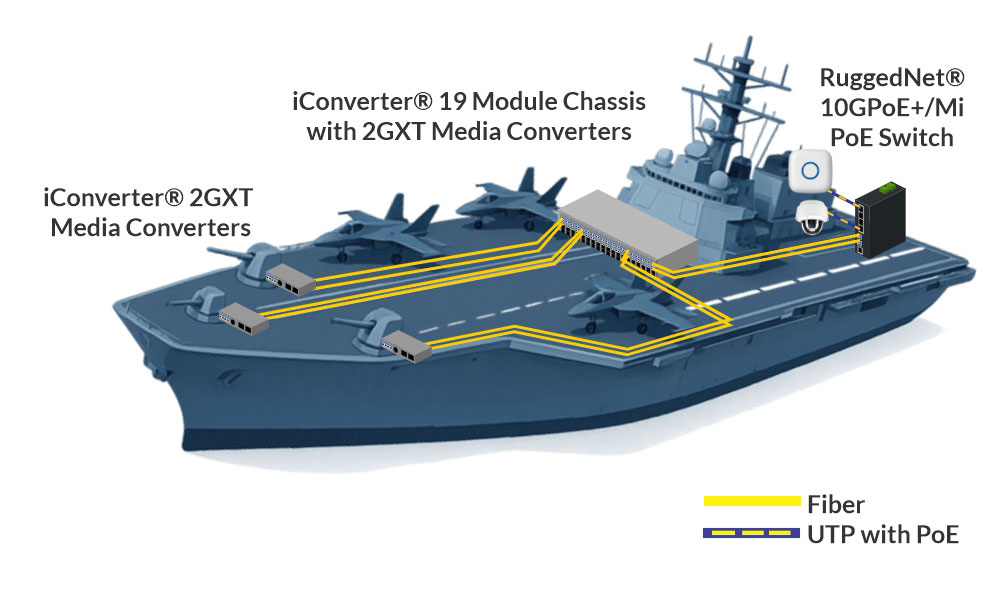

The shipboard network upgrade utilized a combination of Omnitron iConverter® and RuggedNet® technologies to create a unified, high-reliability architecture.

iConverter 2GXT Dual-Channel Media Converters

Chassis-Based: Installed in 19-module iConverter chassis to provide managed fiber-to-copper conversion, redundancy, and centralized control for onboard systems.

Standalone Units: Hardened converters deployed near weapons and control systems enabled point-to-point fiber extensions and edge protocol conversion.

RuggedNet 10GPoE+/Mi Industrial PoE Switches

Distributed throughout the ship to power and connect IP cameras, wireless access points, and security systems.

Delivered MultiGigabit Ethernet performance with fiber uplinks to the managed backbone.

Simplified deployment by combining PoE+ power and data over a single Ethernet connection in restricted spaces.

Custom Conformal Coating

Omnitron engineered application-specific conformal coatings to protect electronics from salt, humidity, and corrosion—ensuring consistent, long-term operation in demanding marine environments.

Why Omnitron was selected:

Ruggedized, Certified Design: NEBS-compliant hardware withstands extreme shock, vibration, and temperature variations.

Environmental Durability: Optional conformal coatings tailored to maritime exposure.

Compact Form Factor: Ideal for confined shipboard installations.

Flexible Connectivity: Dual-channel converters bridge fiber and copper, supporting both legacy and next-generation systems.

Proven Field Performance: Over 30 years of successful deployment in defense, aerospace, and industrial networks.

Made in the USA: Fully compliant with TAA, BAA, and NDAA standards.

Unified Network Architecture: Seamless integration between iConverter and RuggedNet platforms simplifies deployment and maintenance.

Lifetime Warranty and Support: 24/7 U.S.-based technical support reduces total lifecycle costs.

Results:

Through Omnitron’s iConverter and RuggedNet solutions, the naval fleet achieved:

Reliable integration between fiber and copper infrastructures.

Enhanced protection against salt fog, corrosion, and humidity.

Stable, resilient performance in mission-critical environments.

Simplified power and data delivery through PoE+ technology.

Streamlined logistics with fully compliant, U.S.-manufactured equipment.

Contact us today to see how we can assist you in your upgrades.

Products Used in this Solution:

iConverter 2GXT Standalone Media Converters

iConverter rack mount 2GXT Media Converters

iConverter 19-Module Chassis